QC Finder is a revolutionary tool designed to enhance your visual inspection processes. With its intuitive interface, QC Finder empowers you to rapidly identify and document defects with ease. Our advanced functions allow for precise evaluation, ensuring consistent and reliable quality control across your workflows. Say goodbye to time-consuming manual inspections and embrace the power of automated visual assessment with QC Finder.

Exceptional QC Images for Exquisite Clarity

In the realm of meticulous craftsmanship and unwavering quality assurance, high-resolution QC photos stand as an indispensable tool. Their images capture every intricate detail with unparalleled accuracy, providing a comprehensive visual record that reveals even the most subtle nuances. From flawless surfaces to precise configurations, high-resolution QC photos offer an unblemished view of the product's integrity.

Utilizing cutting-edge technology and expert technicians, we generate high-resolution QC photos that meet industry standards. Our images are adjusted for clarity and detail, enabling a thorough assessment of every aspect of the product.

By leveraging the power of high-resolution QC photos, we provide an unwavering commitment to quality control, fostering customer trust and satisfaction.

Streamlining QC with Powerful Image Analysis

Accelerating QC processes is a top priority for companies of all sizes. Traditionally, QC has relied on manual inspections, which can be time-consuming and prone to human error. However, the advent of advanced image analysis technologies has revolutionized this industry, enabling higher throughput and more accurate QC procedures. By employing machine vision algorithms, software can rapidly inspect images for defects, inconsistencies, or variations more info that may be subtle to detect by the human eye.

- These automated

- immediate feedback,

- reducing lead times and enhancing overall production efficiency.

Furthermore, image analysis delivers valuable insights that can be used to detect trends, fine-tune processes, and avoid potential issues before they arise.

QC Images: Ensuring Quality at Every Stage

In the digital realm, where visuals reign supreme, delivering high-quality images is paramount. Comprehensive quality control (QC) process ensures that every image meets stringent standards from conception to final release. This involves a multifaceted approach encompassing automated tools and expert human review at each stage of the workflow.

Early QC focuses on source content, verifying resolution, format, and licensing compliance. Throughout the editing process, designers utilize software to rectify flaws such as color inconsistencies and sharpness problems. Towards the end of the workflow, final images undergo a thorough QC inspection, highlighting any remaining discrepancies before distribution.

This meticulous process guarantees that every image reflects the highest quality, boosting user experience and preserving the reliability of visual content.

Unleash the Power of QC Photography

QC photography isn't just about snapping pictures; it's a discipline that enhances ordinary moments into extraordinary artwork. By utilizing precise techniques, QC photographers create breathtaking imagery that impacts viewers on a deep level. Whether it's freezing fleeting moments of beauty or telling compelling stories, QC photography has the ability to inspire.

Mastering Precision with QC Images

Stepping into the realm of Quality Control (QC), we discover a world where meticulous observation guides success. Visual inspection, a cornerstone of this process, relies on images as powerful tools to reveal subtle discrepancies. QC images are more than just snapshots; they are windows into the performance of products and processes. By analyzing these visual cues, engineers and technicians can pinpoint potential issues before they develop into larger problems.

- QC images enable data-driven decision making, ensuring that products meet the highest standards.

- They provide a visual record of the manufacturing process, improving traceability and accountability.

- Additionally, QC images can be combined with other data sources to create a comprehensive picture of product quality.

Through visualization, we can transform complex technical information into actionable insights. By embracing the power of QC images, we unlock the potential for continuous improvement and realize excellence in every aspect of product development and manufacturing.

Luke Perry Then & Now!

Luke Perry Then & Now! Patrick Renna Then & Now!

Patrick Renna Then & Now! Tina Majorino Then & Now!

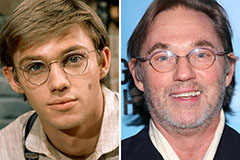

Tina Majorino Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!